The Science of Perfectly Pulled Meat: Timing, Temperature & Texture

Master low & slow with a pitmaster’s understanding of collagen, stalls, and the path to silky strands.

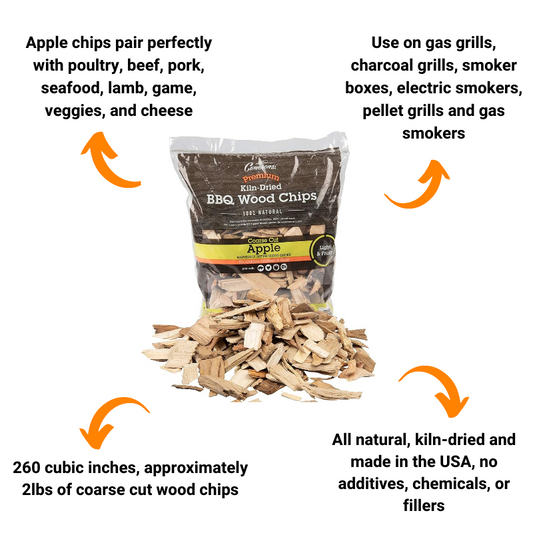

When it comes to barbecue, few things capture the heart of pitmasters and backyard cooks alike like pulled meat. Whether it’s pork shoulder, beef chuck, or chicken thighs, the moment you shred tender strands of smoky, juicy meat is pure magic. But there’s more to it than tossing meat on the smoker and waiting for it to “fall apart.” Achieving perfectly pulled meat is equal parts science, technique, and patience.

In this deep dive, we’ll break down the science of timing, temperature, and texture so you can nail pulled perfection every single time.

Why Low & Slow is the Golden Rule

Pulled meats are made from tougher cuts like pork shoulder (Boston butt), beef chuck, or brisket point. These cuts are loaded with connective tissue (collagen) and fat—the very things that make them tough at first, but irresistible when cooked properly.

- At lower pit temps (225–250°F), collagen slowly breaks down into gelatin, delivering that silky, juicy mouthfeel.

- Fat renders gradually, basting the meat from the inside out.

- Rushing with high heat leads to chewy, dry chunks instead of luscious strands.

Understanding the Stall

Around an internal temperature of 155–165°F, meat “stalls” and seems to stop climbing for hours. This is evaporative cooling: surface moisture evaporates and cools the meat, offsetting heat from the smoker.

- The stall can last 1–5 hours depending on cut size, humidity, and cooker airflow.

How to handle it:

- Patience: Let it ride for maximum bark development.

- Texas Crutch: Wrap in butcher paper (better bark) or foil (faster cook) once bark is set (~160°F).

The Target Zone: 195–205°F

“Safe to eat” isn’t the same as “ready to pull.” For pulled texture, push the meat into the 195–205°F internal range:

- Connective tissues fully convert to gelatin.

- Fibers relax and separate easily.

- Past ~205°F, risk of dryness rises—especially on leaner muscles.

Resting: The Unsung Hero

Pulling meat straight off the pit causes juices to spill out. Instead, wrap and rest so juices redistribute:

- Wrap in foil or butcher paper and place in a resting blanket, warm oven (around 150°F) or a cooler wrapped in old towels.

Need a resting blanket? We've got you covered in the Pitmaster Shop: - Rest 30–60 minutes (bigger cuts can go longer).

Shredding Like a Pro

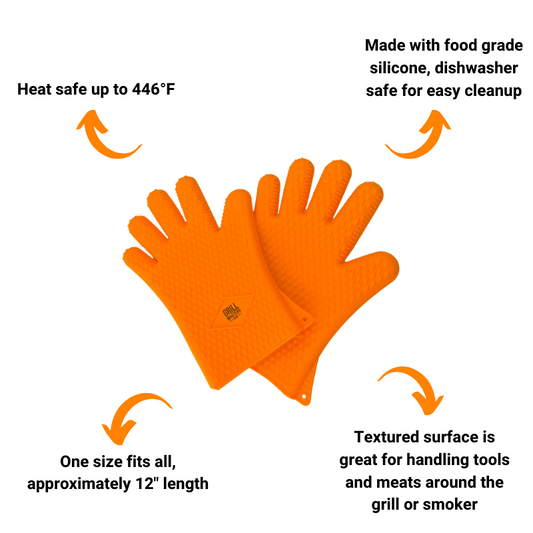

- Gloved Hands: Best control over strand size while meat is warm.

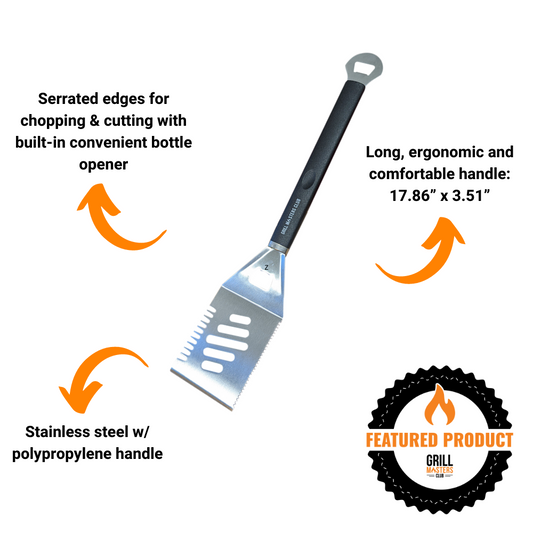

- Meat Claws: Efficient for big shoulders. Need a pair of premium claws? Our meat claws ship for free to US customers -- click here

- Two Forks: Works in a pinch.

Tip: Shred warm for silky strands. Cold meat resists and clumps.

Flavor After the Pull

- Toss lightly with resting juices—this is liquid gold!

- Add sauce gradually for a thin, glossy coat that preserves bark.

- Serve extra sauce on the side so guests can customize.

Troubleshooting Common Issues

- Dry Meat: Often from overshooting temp or skipping rest. Mix in juices, a splash of apple juice, or warm stock.

- Too Tough to Pull: Not cooked enough. If below ~190°F internal, keep cooking.

- Mushy Texture: Overcooked/steamed (wrapped too early or too hot). Aim for steady 225–250°F and wrap after bark sets.

The Bottom Line

- Cook low & slow for collagen-to-gelatin conversion.

- Accept or manage the stall to protect bark and momentum.

- Target 195–205°F internal and confirm with a probe.

- Rest before shredding, then sauce with restraint.

Master these principles and you’ll transform tough cuts into smoky strands of BBQ bliss—every time.

Looking for the perfect sauce and rub combos? Our "Pulled Perfection" box includes two sauces, two rubs, a mop brush and recipe booklet: